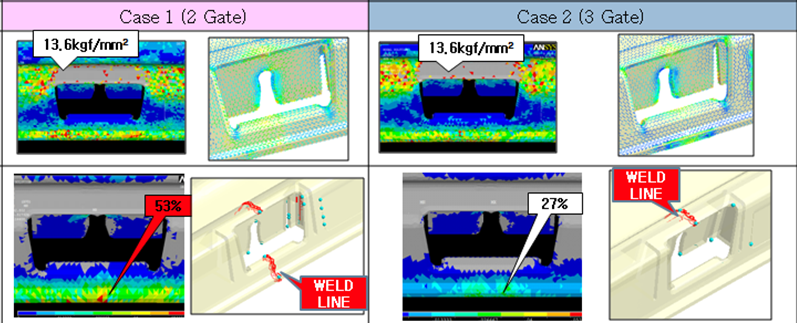

DONGHEE Industrial Co., Ltd. focuses on manufacturing various automotive parts such as chassises, fuel tanks, pedals, sunroofs, axle housings and bodies. The company leveraged on Moldex3D to improve the quality of auto parts. In this case, DONGHEE modified the gate design through Moldex3D simulation results to prevent the cracking problem caused by the weld line on the frame part. On the panoramic sunroof frame part, there’s a problem area which would lead to cracking problem. To prevent the problem, DONGHEE needed to identify where the potential crack location would be and improve the situation. Usually structural stiffness analysis will be performed in order to identify the weak areas. However, the structural analysis does not take the effect of weld lines into consideration; therefore certain important properties of molding process may be neglected. With the help of Moldex3D Advanced Package, DONGHEE was able to indicate the problem areas by validating and optimizing designs in advance so as to reduce errors and improve quality. The original design used two gates. The weld line was found on the easily cracked location. By implementing the injection molding simulation results, DONGHEE also found that there were air traps on the location of the weld line, which might affect the part stiffness and result in cracks. By viewing the result of fiber orientation, it showed that the fiber orientation result of two gate design led to a weld line, which was not stiff enough. Therefore, another three gate design was proposed. The simulation result of the optimized design showed that the weld line location disappeared. Moreover, after observing the air trap locations and the fiber orientation, the result all showed that the stiffness of the crack location had been improved. By using Moldex3D to check different gate designs, DONGHEE successfully improved the part stiffness by changing gate numbers and locations. Without considering the molding properties influence on structural analysis (see Case 1 in chart below), there might be a gap between the analysis result and the real situation. Thus, it is necessary to consider the effect of injection molding process when performing structural analysis. As a conclusion, the structural analysis with the integration of molding process (see Case 2 in chart below) properties shows that the gate location will have impact on both the locations of weld lines and cracks. Furthermore, it is found that changing the numbers and the locations of gates will improve the part stiffness and prevent cracks from happening. By using Moldex3D to investigate and optimize different gate designs, DONGHEE successfully strengthened part stiffness and enhanced the product quality right at the early development stage. Freezer Working Room,Cryogenic Freezer Working Room,FRP Freezer Working Room Inamori Technology (Wuxi) Co., Ltd. , https://www.carbonfibrefactory.com![]()

Executive Summary

Challenges

Solutions

Case Study

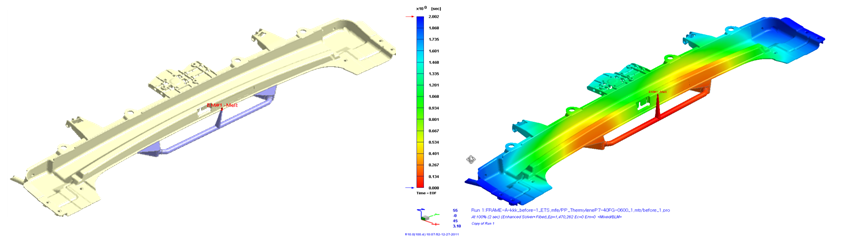

Original two-gate design and its simulation result

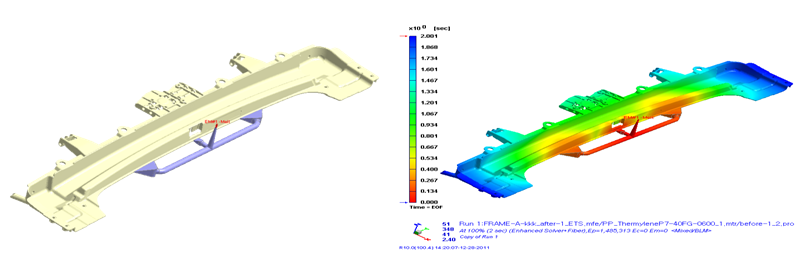

Original two-gate design and its simulation result Optimized three-gate design and its simulation result

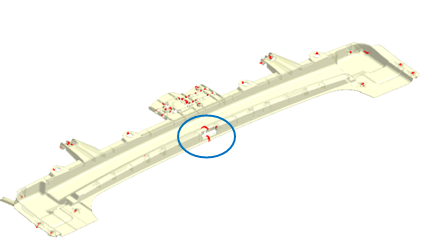

Optimized three-gate design and its simulation result Original design: The weld line location (shown in blue circle) caused cracking problem.       Â

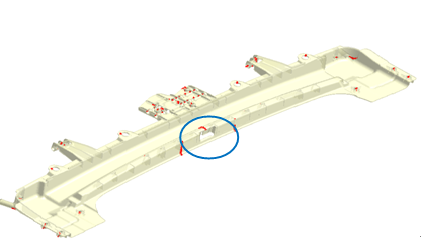

Original design: The weld line location (shown in blue circle) caused cracking problem.         Optimized Design: The weld line location disappeared, and the part strength had been improved.

Optimized Design: The weld line location disappeared, and the part strength had been improved.

Customer Profile