In the world of metal fabrication, choosing the right press brake machine controller is paramount for precision and efficiency. The numerical control system of the press brake is a system that controls the machine's procedures through a series of programming. The control system of the press brake is divided into NC and CNC controllers. Both CNC and NC controller are used to ensure the positioning accuracy of the press brake tooling and backgauge. Their main difference lies in whether the program allows modification. The numerical control system cannot modify the program, while the CNC system can modify or edit the program. The CNC system is an advanced version of the NC system that greatly improves the accuracy and efficiency of the bending operation. The CNC system is also user-friendly and can enhance work efficiency. It contains various programming functions that can store a large number of complex bending steps, allowing for the production of large quantities of complex workpieces faster. A good control system can optimize procedures and improve production efficiency. However, do you know which press brake controller is the best choice? This article will introduce how to select the right press brake controller. Before starting, let's watch the video first. CNC press brake controllers can generally be divided into manual and CNC controllers. The manual controller requires the operator to have a good understanding of bending parameters and requires manual adjustment and monitoring of machine operation. The operation of manual controllers is time-consuming and has low accuracy. The CNC controller controls the operation of toolings, ram, and back gauge through computer software. Simply edit the relevant parameters to bend the workpiece accurately. CNC controllers are compatible and adaptable with various bending machines. Delem, founded in the Netherlands in 1978, is a leading enterprise focusing on the CNC control field of sheet metal bending manufacturing. Delem's press brake control systems include DA-Retrofit solutions, DA-40 series, DA-50 series, and DA-60 series. The DA-66T, 69T, 53T, 58T, 41T, and 42T of Delem CNC control systems are touchscreen versions. While DA-66W and 65R CNC control systems are button versions. Delem has a variety of touchscreen versions of the CNC controller. DA-40 series This is a video of the company’s experience using the Delem DA42T control system: The controller of this series is specially used for traditional torsion shaft press brakes. The system is able to control the back gauge(X&R), and beam(Y). The bright LCD screen can be used for programming parameters including angle, tool, and material. The DA-42 also has the functions of crowning control and pressure control. DA-50 series This is a video of our company’s experience using the Delem DA58T control system: DA-58T is suitable for the electro-hydraulic synchronous press brake. DA-58T provides 2D touch graphic programming to calculate the bending process and collision detection automatically. The positions of all axes are calculated automatically. The bending process is simulated by the real scale machine and toolings. DA-58T also can be used for tandem operation. DA-53T is able to control Y1, Y2, and two auxiliary axes. DA-60 series This is a video of our company’s experience using the Delem DA69T control system: The DA-60 series offers 2D and 3D full touch screen graphics programming. The DA-69T and DA-66T are suitable for bending procedures requiring high accuracy. The DA-66T offers 2D programming that includes automatic bend sequence calculation and collision detection. The system is modular, the program is expanded, and the operation is more flexible. Delem's two common button version controllers are the DA-66W and the DA-65R. These two systems provide 2D graphic programming and 3D graphic display functions. They also offer a multi-machine linkage function, and the touch screen is an optional configuration. Founded in Italy in 1962, Automation is a world-leading expert in the field of integrated CNC systems. By 2022, ESA's products will mainly include the 600 and 800 series. Commonly used are the S660, S640, S630, S830, S840, S850, etc. This is a video of our company’s experience using the ESA S640 control system: The S600 series are all touch screens. They can control a minimum of 3 axes and a maximum of 128 axes. The PLC and HMI can be reprogrammed to meet customized requirements. They can adapt to a variety of bending machines, including hydraulic press brakes, synchronous hydraulic press brakes, electric press brakes, and tandem press brakes, etc. This is a video of our company’s experience using the ESA S860 control system: The S800 series is a new product line launched by the company in 2020. The innovation of the S800 series is mainly reflected in intelligent modularization, complete digitalization, and wireless network connection. The screen is 100% full touch, and graphical tools can develop complex 3D interfaces. Cybelec, founded in Switzerland in 1970, is a world-famous manufacturer of computer numerical control software for metal forming. Cybelec's CNC system includes button versions: CT8P, CT8PS, CT8PS, CT15P, and the touch screen version: VisiTouch series. The following is a video of our company’s experience using the Cybelec VT19 controller: The Cybtouch series is equipped with the Cybtouch tool, which can be used for wireless transmission between PC and system. Modern streamlined glass surface touch screens can be used with gloves. The touch screen provides 2D or 3D graphics programming, which can be programmed directly. Automatic calculation of bending sequence, angle measurement, and collision detection. It can control multi-axis movement and can be used for tandem press brakes. Disadvantages: When choosing a press brake controller, consider your specific needs and budget: Modern press brake machines are equipped with advanced controllers, and different brands and models of press brake controllers may have their superiority. Before selecting the advanced press brake controller, it is necessary to thoroughly understand its function and brand and then select the appropriate controller according to the budget. The most important points in choosing a controller for a press brake are functionality, stability, ease of use, and safety. User-friendly controllers can provide you with efficient working time and outstanding levels of productivity and performance. High-quality controllers are designed to ensure bending accuracy. In my article, I discuss three advanced press brake controller brands that can give you the very best user experience. ESA rapidly upgrades its wide range of products and functions. Delem's products are easy to operate, but they tend to be more expensive. Cybelec's products are of excellent quality, although the operation can be slightly complicated. Upgrading the press brake CNC controller can improve performance and reduce costs. ADH Machine Tool is a professional sheet metal enterprise in the world of press brake manufacturers. If you need to purchase a satisfying press brake, why not contact our product experts and customize the product according to your specific needs? Download the Infographic With High Resolution Reciprocating Non-contact Car Washing Machine Reciprocating Non-Contact Car Washing Machine,Smart Car Washing Machine,Intelligent Car Washing Machine,Car Washing Equipment Xuzhou kushuilong Machinery Equipment Co., Ltd , https://www.kslcarwash.comI. Introduction

1. NC VS CNC Control System

Feature NC (Numerical Control) CNC (Computer Numerical Control) Full Form Numerical Control Computer Numerical Control Input Method Punch tapes and punch cards Keyboards and digital input Program Modification Difficult, requires re-punching cards Easy, can be modified directly on the computer Memory Storage No memory storage for programs Memory available to store and reuse programs Cost Less expensive More expensive Maintenance Cost Lower Higher Operator Skill Requirement Requires highly skilled operators Requires less skilled operators Flexibility Less flexible More flexible Accuracy Lower accuracy Higher accuracy Execution Time More time-consuming Less time-consuming Continuous Operation Cannot run continuously Can run continuously for 24 hours Automation Level Lower automation Higher automation Applicable Scenarios Simple operations like drilling, boring, and milling Complex operations like milling, turning, grinding, and drilling Computational Capability Limited Advanced, with feedback systems for greater accuracy Production Efficiency Lower Higher, suitable for mass production Human Intervention Requires more manual intervention Minimal manual intervention needed Program Storage Programs cannot be stored Programs can be stored and reused Operational Feedback Open-loop system, no feedback Closed-loop system, provides feedback for accuracy 2. Different Types of Press Brake Controllers

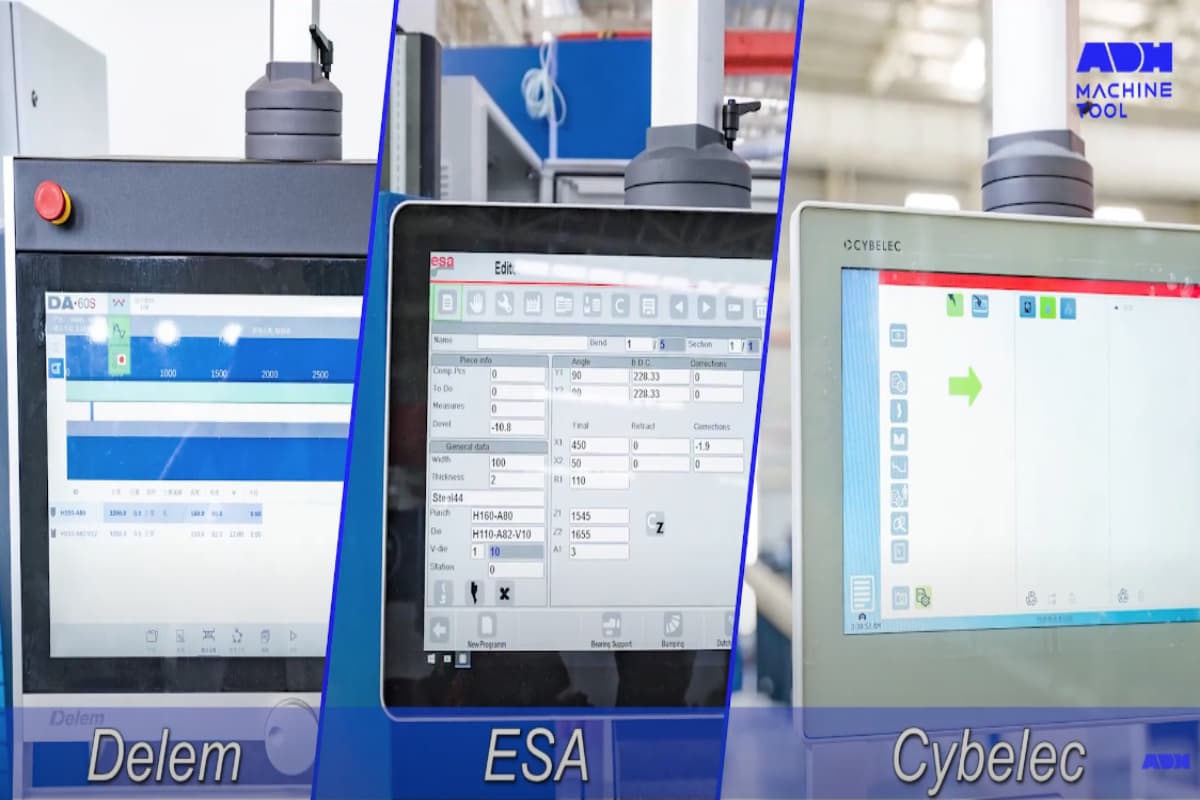

II. Different Brands of CNC Control Systems

1. Delem CNC Control Systems

(1) Touch Screen Version

(2) Button Version

2. ESA CNC Control System

(1) S600 Series

(2) S800 Series

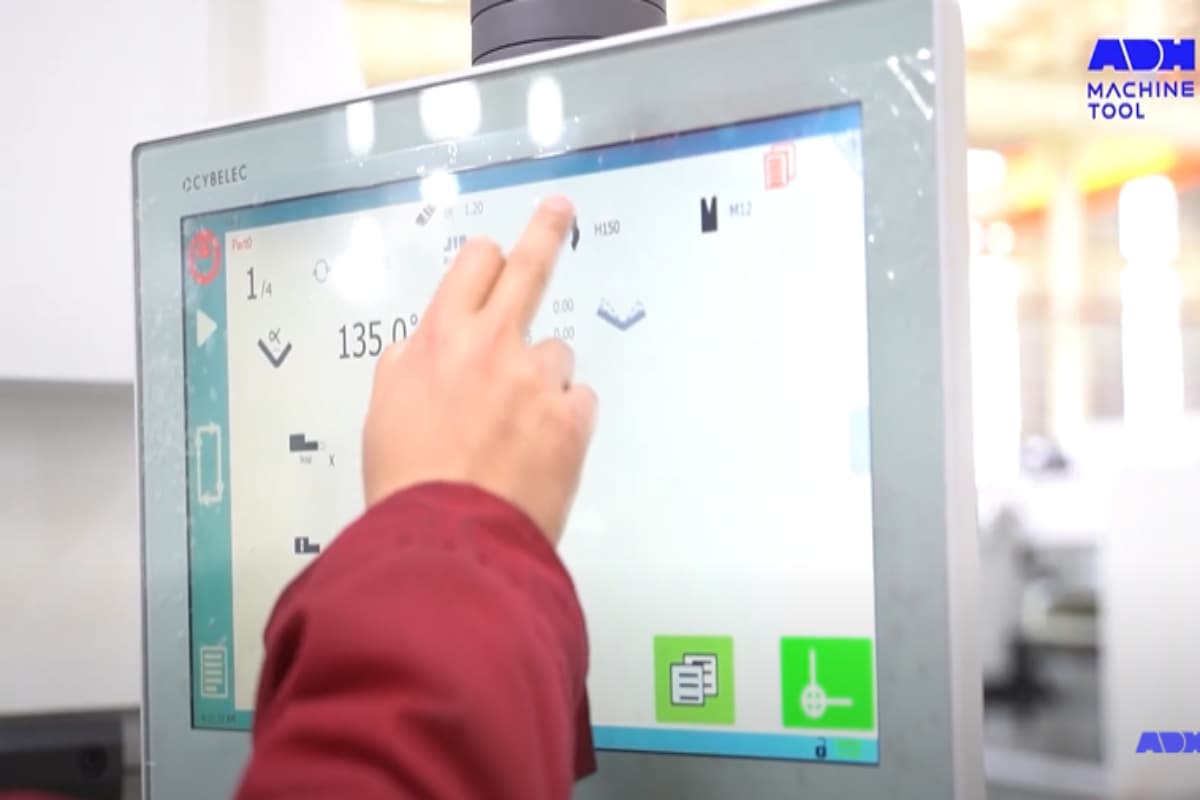

3. Cybelec CNC Control System

III. Press Brake Controller Comparison

Feature/Brand Delem DA-66T ESA 630 Cybelec VisiTouch 19 Display 17" high-resolution color TFT touch screen 10" color touch screen 19" modern streamlined glass surface touch screen Programming Mode 2D graphical programming, automatic bend sequence calculation, collision detection 2D graphical editor and display 2D graphical profile drawing, automatic bend sequence calculation Memory Capacity 1 GB 128 MB silicon disk 32 GB CFAST memory card SATA Axes Supported Up to 8+1 axes Up to 5 axes Multiple axes, including complex bending aids and slave axes Operating System Embedded real-time Windows Not specified Windows 10 User Interface Intuitive touch navigation, optimized ergonomics User-friendly touch screen interface User-friendly HMI, intuitive programming, dedicated set-up wizards Offline Programming Profile-TL offline software One offline software license included Internal backup and restore functions Safety Features Emergency stop switch, sensor bending & correction interface Not specified DSP-TX laser safety system, Y1/Y2 auto compensation Price High Low Medium Ease of Use High, intuitive user interface Medium, suitable for simple to medium complexity operations High, user-friendly interface, quick setup Compatibility Delem Modusys compatibility, USB, peripheral interfacing Suitable for various press brakes including conventional, synchro, hybrid, electric, tandem Compatible with DXF flat pattern and 3D format files Additional Features Full 3D machine setup, multiple tool stations, highly effective control algorithms Advanced graphic programming, sophisticated algorithms, clear and ergonomic HMI Full 3D visualization and simulation, automatic solutions for complex parts

1. ESA Control Systems

Advantages:

Disadvantages:

2. Cybelec Control Systems

Advantages:

Disadvantages:

3. Delem Control Systems

Advantages:

4. Recommendations

V. Conclusion